Basic Ramming Mass

उत्पाद विवरण:

- सतह की फ़िनिश Powder Coated

- प्रपत्र Solid

- शुद्धता (%) 99%

- रीफ्रैक्टरीज के प्रकार बेसिक रिफ्रैक्टरी

- शेप पाउडर

- सरंध्रता सिरेमिक

- आयामी स्थिरता

- Click to view more

बेसिक रैमिंग मास मूल्य और मात्रा

- टन/टन

- 1

- टन/टन

बेसिक रैमिंग मास उत्पाद की विशेषताएं

- Powder Coated

- सिरेमिक

- Solid

- पाउडर

- 99%

- बेसिक रिफ्रैक्टरी

बेसिक रैमिंग मास व्यापार सूचना

- 1 प्रति महीने

- 1 हफ़्ता

- मानक

- ऑल इंडिया

उत्पाद विवरण

Basic Ramming Mass

When it comes to buying Basic Ramming Mass, our company tops the list of well known manufacturers, suppliers and exporter of these. We are the only company to provide these material to customers according to the furnace capacity and users needs. In order to have remarkable mixture, we make sure to do proper mixing of less wastage, binders, and use boric acid. To give clients superior results, we work devotedly and offer them ramming mass according to their furnace make and capacity, In addition to this, provided high quality Basic Ramming Mass are subject to normal aging and are suggested to use within suggested time.

Features:

- Fine finish

- Sturdy construction

- Thermal resistance

- Extended durability

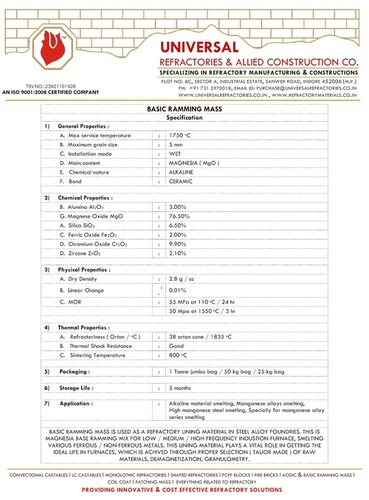

| General Properties | |

| A. Max service temperature | 1750 °C |

| B. Maximum grain size | 5 mm |

| C. Installatiion mode | WET |

| D. Main content | MAGNESIA(MgO) |

| E. Chemical nature | EALKALINE |

| F. Bond | CERAMIC |

| Chemical Properties | |

| B. Alumina Al2O3 | 3.00% |

| G. Magnese Oxide MgO | 76.50% |

| A. Silica SiO2 | 6.50% |

| C. Ferric Oxide Fe2O3 | 2.00% |

| D. Chromium Oxide Cr2O3 | 9.90% |

| D. Zircone ZrO2 | 2.10% |

| Physical Properties | |

| A. Dry Density | 2.8 g /cc |

| B. Linear Change | 0.01% |

| C. MOR | 55 MPa at 110oC/24hr |

|

| 50 Mpa at 1550°C/3hr |

| Thermal Properties | |

| A. Refractoriness ( Orton / °C ) | 38 orton cone / 1835 °C |

| B. Thermal Shock Resistance | Good |

| C. Sintering Temperature | 800 °C |

| Packaging | 1 Tonne jumbo bag/50kg bag/25 kg bag |

| Storage Life | 5 months |

| Application | Alkaline material smelting, Manganese alloys smelting, High manganese steel smetling, Specially for manganese alloy series smelting |

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें