Refractory White Heat K Castable

38000.00 INR/Ton

Product Details:

- Surface Finish Fine and smooth after setting

- Density 2.6 Gram per cubic centimeter(g/cm3)

- Melting Point 1770C and above

- Water Absorption <10%

- Application Furnaces, kilns, boilers, incinerators, foundries, and other high-temperature industrial units

- Usage & Applications Suitable for lining and repairing all types of high-temperature industrial furnaces and equipment

- Purity(%) High purity

- Click to view more

X

Refractory White Heat K Castable Price And Quantity

- 1 Ton

- 38000.00 INR/Ton

- 30-60 Minutes

- > 500 kg/cm²

- Store in Cool and Dry Place

- Vibration Casting / Pouring

- Up to 6-12 months when unopened

- Graded

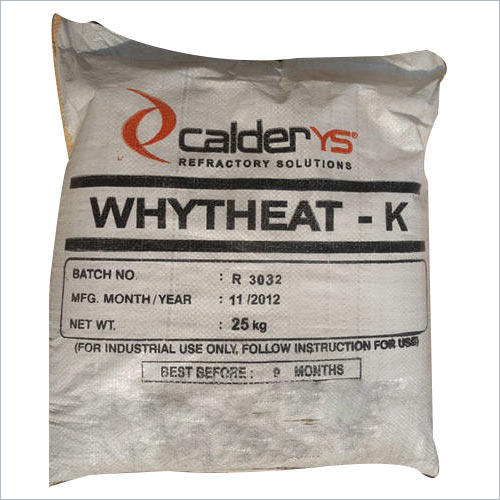

- Packaged in HDPE Bags

- 2.4 - 2.5 g/cm³

- Up to 1600°C

- Hydraulic

Refractory White Heat K Castable Product Specifications

- AlO: 50-60%, CaO: 6-8%, FeO: <2%

- High cold crushing strength (typically 70-90 MPa after firing)

- N/A (refractory castables rated by strength rather than standard hardness)

- Furnaces, kilns, boilers, incinerators, foundries, and other high-temperature industrial units

- Low apparent porosity (usually 15-20%)

- 2.6 - 2.8 g/cm

- Powder/Granular for mixing and casting

- High purity

- Low, typically 1.25 - 1.5 W/mK at 1000C

- Suitable for lining and repairing all types of high-temperature industrial furnaces and equipment

- Excellent volume stability at high temperatures

- White to off-white

- Powder/Granular (Castable form)

- <10%

- 1770C and above

- 2.6 Gram per cubic centimeter(g/cm3)

- Fine and smooth after setting

- High Alumina Castable

- Monolithic Refractory

- 30-60 Minutes

- > 500 kg/cm²

- Store in Cool and Dry Place

- Vibration Casting / Pouring

- Up to 6-12 months when unopened

- Graded

- Packaged in HDPE Bags

- 2.4 - 2.5 g/cm³

- Up to 1600°C

- Hydraulic

Refractory White Heat K Castable Trade Information

- 1 Ton Per Month

- 1 Week

Product Description

Step into the spotlight with our Refractory White Heat K Castable, a sought-after, best-seller in high-temperature industrial lining solutions. Boasting a resplendent white to off-white finish, this supreme bulk density castable (2.42.5 g/cm after firing) delivers exceptional performance in environments up to 1600C. Its graded particle size, hydraulic bonding, and low porosity ensure dimensional stability and a superior, smooth surface. Procure this premium monolithic refractory, renowned for its high strength and purity, for your furnaces, kilns, boilers, and more. Secure and seamless, HDPE packaging protects freshness for long shelf life.

Versatile Applications and Premium Performance

Refractory White Heat K Castable is expertly used for lining and repairing high-temperature industrial units such as furnaces, kilns, boilers, incinerators, and foundries. This monolithic refractory is ideally applied through vibration casting or pouring methods, resulting in a fine, smooth finish. Its robust nature ensures supreme protection against intense heat, making it a go-to solution for heavy-duty commercial and industrial applications across various demanding sites.

Domestic Excellence, Swift Global Reach

Widely recognized in the Indian domestic market, Refractory White Heat K Castable is also a prime choice for the export market. With ample supply ability to meet bulk needs, we ensure prompt order processing and offer express shipping options for time-sensitive projects. Our streamlined delivery system guarantees that your castable arrives in optimal condition, helping you maintain project timelines whether youre a local manufacturer or a global importer.

Versatile Applications and Premium Performance

Refractory White Heat K Castable is expertly used for lining and repairing high-temperature industrial units such as furnaces, kilns, boilers, incinerators, and foundries. This monolithic refractory is ideally applied through vibration casting or pouring methods, resulting in a fine, smooth finish. Its robust nature ensures supreme protection against intense heat, making it a go-to solution for heavy-duty commercial and industrial applications across various demanding sites.

Domestic Excellence, Swift Global Reach

Widely recognized in the Indian domestic market, Refractory White Heat K Castable is also a prime choice for the export market. With ample supply ability to meet bulk needs, we ensure prompt order processing and offer express shipping options for time-sensitive projects. Our streamlined delivery system guarantees that your castable arrives in optimal condition, helping you maintain project timelines whether youre a local manufacturer or a global importer.

FAQs of Refractory White Heat K Castable:

Q: How is Refractory White Heat K Castable typically installed?

A: This product is expertly installed using vibration casting or pouring methods, ensuring optimal packing density and a smooth, fine surface finish after setting.Q: What are the main application areas for White Heat K Castable?

A: It is used for lining and repairing industrial furnaces, kilns, boilers, incinerators, and foundries that operate at high service temperatures up to 1600C.Q: When should the castable be used after opening the packaging?

A: It is best to use the castable immediately after opening to maintain its high purity and supreme performance; unopened, it remains stable for up to 612 months.Q: What are the advantages of using this castable over conventional bricks?

A: White Heat K Castable exhibits superior volume stability, low porosity, and high cold crushing strength after firing, making it more adaptable for complex shapes and repairs than traditional refractory bricks.Q: Where can the Refractory White Heat K Castable be sourced from?

A: It is available directly from reputable exporters, manufacturers, producers, and suppliers in India, with flexible order processing and global shipping capabilities.Q: What benefits does this product provide for high-temperature industrial processes?

A: It offers excellent thermal insulation, low thermal conductivity, and strong dimensional stability, ensuring equipment longevity and process efficiency in harsh industrial environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'White Heat Castable' category

Back to top

Call Me Free

Call Me Free